7 The external environment, preparedness and safety

From the very beginning, consideration for other industries and safeguarding the external environment has formed an integral part of how Norway manages its petroleum activities. Over the course of 40 years, we have developed an extensive system of policy instruments designed to safeguard considerations for other industries and the external environment in all phases of the activity – from opening of new areas, via license awards, exploration, development and operation, through field cessation.

Emissions from the petroleum activity are often divided into three different categories: operational discharges to sea, operational emissions to air and acute discharges/emissions. Acute discharges/emissions are emissions or discharges that are not planned, and would not be permitted under the Pollution Control Act. Operational discharges to sea are mainly cleaned water that originates from the reservoirs (produced water) and drilled rock mass (drill cuttings) that originates from drilling activity. Emissions to air are largely exhaust from energy production needed to operate the facilities. In addition, some gas is combusted through flaring for safety reasons, as well as evaporation of light oil components in connection with storage and loading of crude oil.

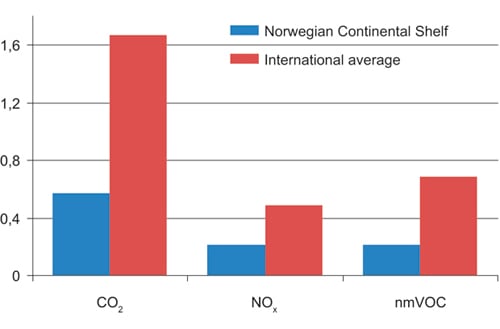

As a consequence of a number of policy instruments established through more than 40 years of petroleum activity as well as strong focus on limiting emissions/discharges on the part of authorities and companies, the Norwegian Shelf is among the best in the world when it comes to emissions to air per produced unit, cf. Figure 7.1.

Figur 7.1 Emissions to air on the Norwegian Shelf compared with international average for other petroleum-producing countries for the year 2008. Unit in 100 kg per scm o.e. for CO2 and in kg per scm o.e. for other components.

Kilde: OLF and EnvironmentWeb.

A goal has been established of zero environmentally hazardous and environmentally harmful discharges to sea (the zero discharge goal). This goal is regarded as having been achieved as regards environmentally hazardous chemical additives, while the goal for discharges of oil and naturally occurring environmentally hazardous substances in produced water has not been achieved to the same degree. In 2007, 90 per cent of the chemical substances discharged consisted of substances that are not considered to pose a danger to the marine environment. Today, some of the water that accompanies petroleum produced from the reservoirs is reinjected. This allows us to avoid discharging oil drops and chemical residues that remain after the water is cleaned. At the same time, this causes energy consumption on the facility, when the water is forced back into the subsurface.

The two largest acute spills to take place on the continental shelf were the blowout on the Bravo platform in 1977 and an accident in connection with oil loading on the Statfjord field in 2007. No acute spills on the continental shelf have ever reached the coast. Every day, both the companies and the authorities focus on diligent management of the risk associated with the activities to make sure that this will not happen in the future. Safety standards on the Norwegian Shelf are high.

Forty-five years of petroleum activity on the Norwegian Shelf have proven that production of oil and gas can be compatible with environmental considerations. However, there is still work to be done and the players must continue their efforts to find efficient new solutions that further reduce emissions and discharges from the activity. Comprehensive assessments in connection with establishing new targets and cost-efficient use of policy instruments to achieve these targets are important, and we have proven that it is possible to balance various environmental considerations.

The administrative responsibility for the petroleum sector is divided among several ministries and directorates. The Ministry of Petroleum and Energy and the Norwegian Petroleum Directorate are responsible for ensuring sound and prudent management of the oil and gas resources. The Ministry of Labour and the Petroleum Safety Authority Norway are responsible for health, working environment and safety. In an upcoming Storting white paper on working environment, working conditions and safety in Norwegian working life, the Ministry of Labour will present a broader, updated review of the state of HSE in the petroleum activities. The Ministry of Fisheries and Coastal Affairs, represented by the Norwegian Coastal Administration, is responsible for the State’s preparedness against acute pollution, and for coordinating private, municipal and State players in a national emergency preparedness system. The Ministry of the Environment and the Climate and Pollution Agency are responsible for regulating emissions to air and discharges to sea through discharge permits, as well as for stipulating preparedness requirements for acute pollution in the petroleum activities. In an upcoming Storting white paper on Norwegian climate policy, the Ministry of the Environment will present a broad-based review of the status and objectives of our climate policies.

7.1 Comprehensive and modern regulation

The petroleum activities are subject to strict requirements for safeguarding the external environment. A thorough and comprehensive system has been established consisting of e.g. management plans, impact assessments, emission/discharge permits and financial policy instruments. To ensure the best possible follow-up, the health, safety, environment and working environment authorities have worked together to develop integrated comprehensive regulations for health, safety and the environment.

Cost-effective use of policy instruments is a fundamental principle for management of the petroleum resources in Norway. This entails conducting cost-benefit assessments of measures that reduce emissions to air and discharges to sea, and implementation of the measures with the lowest cost first. The principle of cost-effectiveness is also a fundamental element in Norwegian climate policy. The polluter must pay, and the environmental and climate goals shall be achieved through the use of cost-effective policy instruments. The petroleum industry in Norway has paid a CO2 tax since 1991, and has also been part of the emission quota system since 2008.

A general framework is established through the management plans to balance commercial interests with safeguarding the external environment. Extensive technical assessments underpin the decisions regarding terms and conditions for new petroleum activity in the management plan areas. These area-based conditions are stipulated particularly on the basis of balanced consideration between the petroleum and fishery industries, as well as the environment.

An opening process must be carried out before an area can be opened for petroleum activity. The purpose of an opening process is to study the technical basis on which the Storting (Norwegian Parliament) will base a potential decision to open an area. An opening process includes mapping the resource base for petroleum. An evaluation shall also be made of the commercial and environmental effects of potential petroleum activity, the potential hazard of pollution, along with the economic and social effects that may result from the petroleum activity. This is accomplished by means of an impact assessment.

As regards acquisition of seismic data, notification of this activity must be provided to the authorities five weeks before the activity commences. Furthermore, restrictions apply to seismic data acquisition in the most vulnerable areas through the management plans. Such restrictions can include time restrictions for such activity e.g. during spawning migration or spawning. This will contribute to preventing acquisition of seismic data when the natural resources can be particularly vulnerable. There are also requirements for a fishery expert to be on board the vessel during acquisition of seismic data. The fishery expert shall function as a connection between the petroleum and fishery industries, so that both industries can carry out their work in the best possible manner.

Strict requirements are stipulated for exploration drilling. An exploration drilling permit must be obtained from the Norwegian Petroleum Directorate for each well to be drilled. These permits presume that permission for activity under the Pollution Control Act and consent to conduct exploration drilling are secured from the Climate and Pollution Agency and the Petroleum Safety Authority Norway, respectively. The management plans also stipulate restrictions on exploration drilling in particularly vulnerable areas, e.g. as regards spawning.

As part of a development plan (PDO/PIO) for individual fields, the operator must, among other things, study the consequences on nature and the environment if the discovery in question is developed. The study should describe potential climate and environmental effects of expected emissions/discharges, as well as potential limitation measures to reduce the emissions/discharges. Both the study program and the actual impact assessment must be submitted for consultation to affected stakeholders. The purpose of this is to ensure a broad-based, open process.

Since 1996, power from shore has been considered in connection with all new or revised development plans. This has contributed to several fields deciding to meet their energy needs with power from shore. Today, nearly 40 per cent of Norwegian gas production is carried out with power from shore. Large new power supplies to the petroleum sector have consequences for the power grid and reliability of supply on land and on the facilities. This must all be seen in context.

In the operations phase, emissions and discharges are regulated via permits under the Pollution Control Act, in addition to the continuous economic incentives the companies have to reduce emissions via the CO2 tax, quota obligation for CO2 and NOx tax or payments to the Industry’s NOx fund, in which the companies take active part. The companies must apply to the Climate and Pollution Agency and the Norwegian Radiation Protection Authority for permits under the Pollution Control Act for emissions to air and discharges to sea, and to the Ministry of Petroleum and Energy for flaring permits.

The authorities play a central role in connection with shutting down fields or facilities. The licensees must submit a cessation plan two – five years before a license under the Petroleum Act expires or is relinquished, or when the use of a facility finally ceases. A disposal resolution is made after this plan has been considered by the relevant authorities. This ensures responsible shut down and disposal of the individual facility in terms of safety, environment and resource considerations.

Research and development are important to achieve more environmentally friendly production on the Norwegian Shelf. A number of projects related to discharges to sea and emissions to air are supported through the DEMO2000 and PETROMAKS research programs. A total of NOK 235 million has been allocated to support such environmental projects in the program period.

Environmental regulation thus takes place at all stages of the activity; from assessment of whether the area should be opened, through exploration, when considering how a field should be developed, through specific permits associated with operation of the field, through annual amendments of these permits and up to cessation of production and disposal of the facilities. This ensures a comprehensive and solid system, where all relevant authorities are involved. Updates of management plans and new impact assessments with updated knowledge shall contribute to ensuring that decisions can be based on the best and most up-to-date factual basis possible. Consultation rounds and submissions provide an opportunity for all relevant players to be heard, while the NOx and CO2 taxes, along with the quota obligation for CO2, give the companies financial incentives to safeguard environmental considerations in daily operations. In addition, the authorities can make administrative decisions in connection with e.g. approval of development plans.

7.2 Operational discharges to sea

Regular discharges to sea are permissible discharges regulated through discharge permits. The discharges can include drill cuttings and produced water containing residues of added chemicals, oil, heavy metals and other naturally occurring substances from the bedrock, including radioactive substances. Chemicals are added in drilling and well operations and in connection with production of oil and gas. The added chemicals are divided into categories – green, yellow, red and black - depending on the properties of the substances.

Chemicals in the green category are substances that are not considered to entail harm or drawbacks for the marine environment. Chemicals in the yellow category are normally not defined as environmentally hazardous, while chemicals in the red and black categories are defined as being hazardous to the environment. Chemicals in the red and black categories are subject to strict control, and discharge is only allowed when warranted by significant safety or technical reasons.

The total volume of chemicals used in 2009 was 480 000 tonnes. Of this, 174 000 tonnes were discharged, 99.9 per cent of which were in the green or yellow categories. The remaining volumes were injected, re-used or handled as waste. With regard to the environmental toxins on the authorities’ prioritisation list, the petroleum activities contribute up to four per cent of the national discharges.

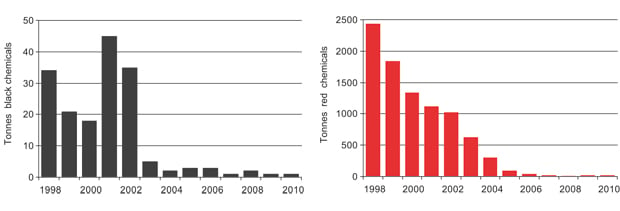

After the goal of zero discharges of oil and environmentally hazardous substances was introduced in 1997, discharges of chemicals in the black category have been reduced from 34 tonnes in 1998 to scarcely 1 tonne in 2010, cf. Figure 7.2. Discharges of chemicals in the red category have been reduced from 2440 tonnes to 16 tonnes in the same period. More than 99 per cent of all environmentally hazardous chemicals have been removed during the last ten years. About 80 per cent of the total chemical discharges occur in connection with drilling and well operations.

This confirms that the work done by operators and the authorities to reduce discharges of environmentally hazardous chemicals on the Norwegian Shelf has yielded results, and that the zero discharge target for these chemicals is considered to be achieved. The efforts to reduce discharges continue, e.g. through examining the possibilities of injecting produced water and drill cuttings, while the substitution work in relation to added chemicals also continues.

Figur 7.2 Discharges of added chemicals from Norwegian petroleum activities, distributed between red and black categories.

Kilde: Norwegian Petroleum Directorate.

The drilled rock mass that comes out of the borehole when drilling for petroleum is called drill cuttings. Drill cuttings have adhering residues of the drilling fluid used during drilling. Whether or not drill cuttings can be discharged to sea often depends on the type of drilling fluid used in the drilling operation. Discharge of drill cuttings originating from drilling operations with water-based drilling fluid (green category) will normally be permitted, while drill cuttings originating from drilling operations with other drilling fluids (oil-based or synthetic) will normally be injected subject to a permit from the Climate and Pollution Agency, or transported to land for treatment and disposal.

If discharge of drill cuttings is allowed, the cuttings will spread out over the seabed in the immediate vicinity of the discharge point. The thickness of the layer will depend on the size of the discharged particles, current velocity in the water masses and the depth at which the discharge occurs. This is the accumulation of cuttings and mud in so-called cuttings piles, and it is assumed that vulnerable organisms such as corals and sponges are sensitive to this accumulation.

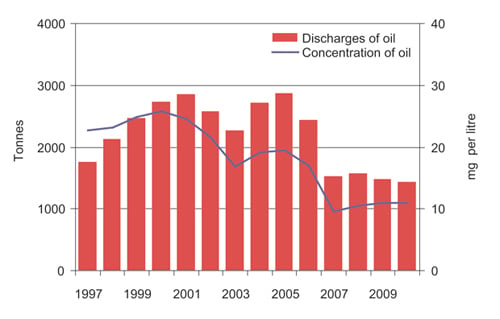

In connection with production of oil and gas, water from the reservoir will follow the wellstream. This water contains residues of added chemicals, oil and other naturally occurring substances, such as heavy metals and radioactive substances. The water is either returned to the reservoir and deposited in a suitable formation, or cleaned and then discharged to the sea. Although the produced water is cleaned before it is discharged, it will still contain small residues of oil and dissolved substances. As a consequence of new cleaning technology and a greater percentage of water that must be injected, both discharges and the concentration of oil in water have been reduced in recent years, cf. Figure 7.3.

The volume of produced water is closely linked to the activity level on the shelf, and to how long the wells have produced. The percentage of water in the wellstream increases the further a field has progressed in its tail production phase. In order to reduce discharges to sea, support is also provided for a number of projects relating to produced water, handling acute discharges to sea and monitoring and detection of spills.

Figur 7.3 Discharges of oil.

Kilde: Norwegian Petroleum Directorate.

The concentration of oil in the produced water discharged to sea in 2009 was about 11 mg per litre. This is well below the maximum level of 30 mg per litre, stipulated in national regulations based on resolutions in the OSPAR Convention for the protection of the marine environment of the northeast Atlantic.

Boks 7.1 Mussels measure discharges

To ensure prudent oil activities on the shelf, accidental polluting spills must be measured efficiently and accurately, and the information must quickly be sent to the right people. The company Biota Guard has started using a biological ”metering tool” to track potential discharges from platforms, in addition to physical and chemical sensors. This “metering tool” is mussels. Biota Guard’s system is based on measuring the health of individual mussels. If the shellfish are exposed to harmful substances or if they experience physical stress due to other threats, the shells close to varying degrees. This can be recorded and measured, and can provide an immediate indication of potential spills. The project receives support from the PETROMAKS program under the direction of the Research Council of Norway.

7.2.1 Policy instruments designed to reduce regular discharges to sea

The zero discharge goal for oil and environmentally hazardous substances to sea from the petroleum activities was established in Storting White Paper No. 58 (1996–1997), Environment policy for sustainable development, and is detailed and clarified in a number of subsequent white papers. The main rule is no discharges of environmentally hazardous substances, neither chemical additives nor naturally occurring substances. It has been stated that the zero discharge objective will be reached within an acceptable framework as regards the environment, safety and economy. In 2005, the Climate and Pollution Agency declared that the zero discharge goal was achieved for added environmentally hazardous chemicals.

Since 2005, the goal of no discharges of environmentally hazardous added chemicals (black and red categories)1 has been regarded as being fulfilled. There will continue to be some discharges of environmentally hazardous substances to sea in the years to come, due to safety and technical considerations. Radioactive substances were also included in the zero discharge objective in 2009.

Norwegian regulations carry out international requirements through the OSPAR Convention for the protection of the marine environment of the northeast Atlantic (the OSPAR Convention). Pursuant to this convention, the oil content of discharges must be as low as possible and no more than 30 mg per litre. Under OSPAR, the chemicals are also characterised according to their inherent properties.

Produced water is normally discharged at a point that is relatively high in the water column, and the most toxic of the water-soluble fractions will rapidly be diluted with seawater. Short-term (acute) effects of regular operational discharges of produced water and drill cuttings are regarded as being insignificant, as these will generally be of a local and temporary nature, with no consequences at the population level. There is more uncertainty surrounding potential long-term effects. Based on current knowledge and monitoring, no consequences have been proven at a population level, however, research in this area is continuing.

As a measure to reduce discharges of produced water, water is injected on several fields without being used for pressure support. This solution will entail higher energy consumption and increased emissions of greenhouse gases. This will often be expensive and technically challenging on older fields. New policy instruments designed to reduce discharges of produced water to sea from the petroleum sector must therefore be viewed in an overall perspective. The discharges to sea must be seen in context with other factors such as emissions to air, generation of waste, safety and costs. The authorities’ assessment is that no general injection requirement should be issued.

The volume of polluting substances in produced water will vary from field to field, as is also the case for the costs of reinjecting this water. On some fields, the costs will be relatively low, e.g. because the field already uses water for pressure support, and the produced water can be used in the pressure support system. On other fields, the quantities of produced water will be relatively small, while the costs of reinjecting the water can be extremely high.

A case-by-case evaluation which takes into consideration both benefit to the environment and possible other upsides compared with the costs of such a solution is a well-established practice in Norwegian resource and environmental management. The Climate and Pollution Agency’s zero discharge report from 2010 concludes in part that no general requirement for injection of produced water should be introduced on the Norwegian Shelf. However, transparent socio-economic cost/benefit analyses, which also include comprehensive environmental assessments of measures to prevent discharge of produced water, should be carried out for new developments. No new factors have emerged that would indicate that the conclusions from the report cannot be applied over the entire shelf.

Stricter requirements were set for discharges to sea in the Barents Sea than for the rest of the shelf. The requirement was introduced in 2003 and entailed that petroleum activities in the area were to be carried out with zero discharges to sea during normal operations, represented by zero discharges to sea of produced water and drilling fluid/cuttings from drilling operations. This policy was adjusted in Storting White Paper No. 10 (2010–2011), Updating of the management plan for the marine environment in the Barents Sea and the waters off Lofoten. In the future, regular discharges to sea from the petroleum activities in this management plan area will be regulated in the same manner as petroleum activities on the other parts of the Norwegian Continental Shelf.

7.3 Emissions to air

In 2009, the petroleum sector was responsible for 27 per cent of the Norwegian emissions of greenhouse gases. This is because the sector is quite large in Norway, the activity carried out is energy-intensive and fossil fuel is not used to any great extent for stationary combustion on the mainland. This is due to extensive use of electricity for heating and generation of electricity that is dominated by hydropower. The greenhouse gas emissions largely consist of exhaust from combustion of gas in turbines, flaring of gas and combustion of diesel. These exhaust gases contain substances including CO2.

The sector is also responsible for significant contributions to other types of emissions. Among the other environmentally harmful substances released are volatile organic compounds other than methane (nmVOC), methane (CH4), nitrogen oxides (NOx) and sulphur dioxide (SO2). CO2 and CH4 are greenhouse gases, while NOx and SO2 contribute to acidification. NmVOC reacts with NOx in the air to form ozone which can e.g. cause diminished plant growth. Exposure to nmVOC can also be hazardous to health, and can entail a working environment problem. Emissions to air from the petroleum activities on the Norwegian Shelf are considerably lower than the international average for oil-producing countries.

Boks 7.2 Greenhouse gases, NOx and nmVOC emissions on the Norwegian Shelf

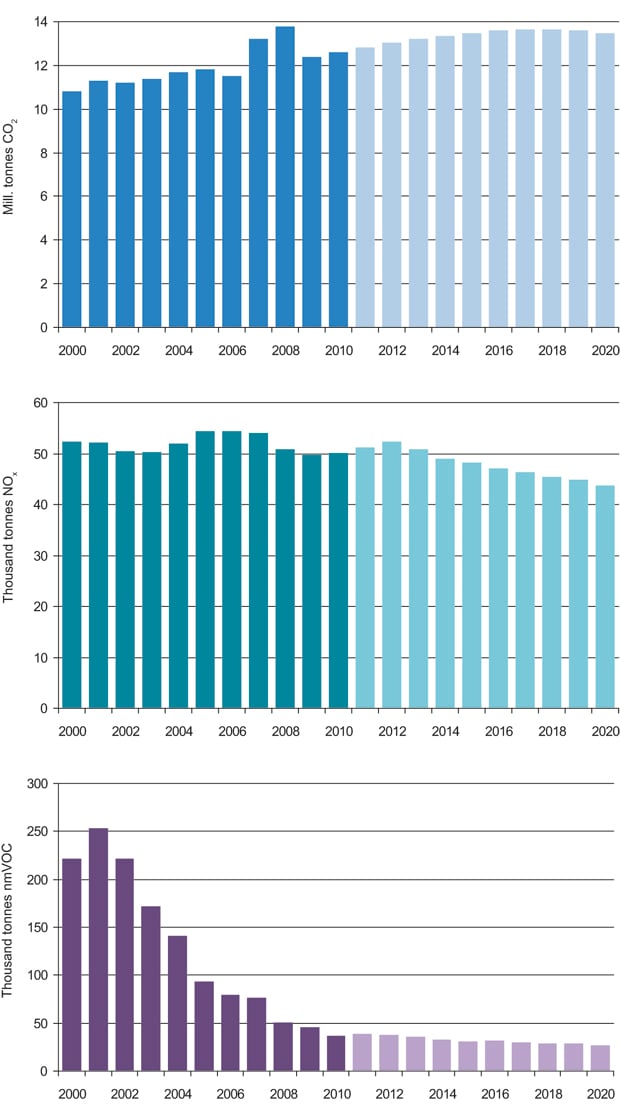

In 2009, total emissions of greenhouse gases in Norway amounted to 51.3 million tonnes of CO2 equivalents. Production of oil and gas accounted for 12.4 million tonnes, or a share of 27 per cent. Greenhouse gas emissions from the facilities on the continental shelf largely originate from combustion of gas in turbines, diesel consumption, and flaring of gas.

It is estimated that greenhouse gas emissions from the petroleum activities in the next few years will be around 14 million tonnes of CO2 equivalents per year. The development in emissions is uncertain, but forecasts indicate that we will reach peak emission level by 2020.

Total NOx emissions in Norway in 2009 amounted to 180 600 tonnes, a decline of 4 per cent from 2008. The petroleum activities were responsible for 49 800 tonnes, which means that the Norwegian Shelf accounts for 29.7 per cent of the total Norwegian emissions. About 65 per cent of the NOx emissions from the Norwegian Shelf come from turbines. NOx emissions from turbines depend on turbine loads as well as the type of fuel. For example, combustion in gas turbines results in lower NOx emissions than combustion in diesel engines.

NOx emissions from the petroleum sector are estimated at about 44 000 tonnes in 2020.

The Norwegian emissions of nmVOC were 141 200 tonnes in 2009. The petroleum sector was responsible for about 45 000 tonnes of this. The emissions in the petroleum sector have been reduced by 82 per cent from the peak year, 2001. The majority of the reduction is due to emission-reducing measures targeting loading and storage of oil on the continental shelf.

NmVOC emissions from the petroleum sector are estimated at about 28 000 tonnes in 2020.

Figur 7.4 Greenhouse gases, NOx and nmVOC emissions on the Norwegian Shelf.

Kilde: Ministry of Petroleum and Energy and Norwegian Petroleum Directorate.

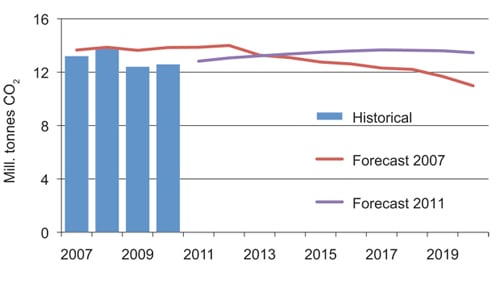

It is difficult to estimate the future development in an industry. A number of factors influence greenhouse gas emissions. Projections are therefore based on a number of technical assumptions for calculation purposes. The uncertainty in the prognoses is also easily illustrated by comparing previous projections with actual emissions. The emissions from the petroleum sector up to 2010 have, for example, been lower than estimates indicated in the spring of 20072. However, the latest emission projections indicate an upward adjustment of the emissions in 2020 by about 23 per cent, from the same point in time, cf. Figure 7.5.

Figur 7.5 CO2 emissions from the petroleum sector.

Kilde: Norwegian Petroleum Directorate.

The development in large parts of the Norwegian Continental Shelf is trending towards more mature fields, while gas transport distances are rising as many of the new gas fields are situated farther from the markets. Gas production makes up an increasingly larger part of the production on the continental shelf. Treatment and transport of produced gas is more energy-intensive than production and transport of liquid. In addition, reservoir pressure declines as the fields age, thus increasing the need for energy in process facilities and for gas compression. Each of these factors alone tends to increase energy needs, which in turn often means greater emissions per produced unit.

Reservoir conditions are another factor that can lead to more need for energy. The further out in the field’s lifetime, the more water in the wellstream. Since the total volume of liquid and gas (water, oil and gas) generally determines the need for energy in the process facility, a field will have higher emissions per produced unit when production declines. Therefore, improving the recovery rate from the fields will also tend to increase emissions per produced unit.

Different types of emissions must be weighed against each other. One example is the connection between discharges to sea and emissions to air. Stricter requirements for e.g. discharge of produced water will lead to increased need for cleaning or injection. These processes demand energy and will entail increased emissions to air. Likewise, efforts to reduce NOx emissions from a facility can impact emissions of CO2, as this entails a special way of operating the turbines. All of these considerations must be sensibly balanced through the correct use of policy instruments.

7.3.1 Policy instruments for reducing emissions to air

Based on resource management considerations, ever since the beginning of the petroleum age, Norway required that all fields have a solution in place for gas. Extensive flaring of gas – a practice with significant associated emissions seen in many other countries – has therefore never been a relevant solution on the Norwegian Shelf. Instead, the gas has become useful, e.g. in meeting the energy needs of purchasers of Norwegian gas on the Continent, or for injection for improved recovery. Flaring gas and cold venting, beyond what is necessary to ensure normal operations, is not permitted pursuant to the Petroleum Act without approval from the Ministry.

The introduction of a CO2 tax in 1991 contributed to development and use of technology which allowed us to switch off the flares. The solution entailed the flare being automatically lit when it was necessary to burn the gas for safety reasons. This contributed to reducing the flare volume. In 2010, flaring was responsible for 11.6 per cent of CO2 emissions from petroleum activities in Norway. This is low compared with other petroleum-producing countries.

The largest source of CO2 and NOx emissions is energy production on the facilities. There are two main ways we can reduce this:

Reduce the energy need

Produce the energy more efficiently and/or with less emissions

The best way to achieve this is to establish policy instruments to ensure that the companies benefit from limiting their emissions. This can be done by setting a cost for the emissions, so that the companies maximize profits when they implement the appropriate emission measures. On the continental shelf, this is accomplished by the companies having to pay CO2 tax and purchase greenhouse gas emission quotas for their emissions. This comes in addition to the value the companies can achieve by exporting and selling their gas instead of using it on the field.

The petroleum sector has paid CO2 tax since 1991, and has participated in the quota system since 2008. Before the petroleum sector joined the quota system, the CO2 tax for the petroleum sector amounted to about NOK 350 per tonne of CO2. When the petroleum sector joined the quota system in 2008, the CO2 tax was reduced to correspond with the level of the quota price, so that the total CO2 cost (tax + quota price) for the petroleum sector would remain at the same level as before. However, the total CO2 cost does vary in step with the quota price, which is also the case for other EU industries subject to a quota system.

Both the CO2 tax and the quota system are cross-sector policy instruments that have had a significant effect in reducing emissions. “Cross-sector” means that these policy instruments cover several sectors. Nevertheless, the CO2 tax is a differentiated tax across sectors, and the petroleum sector are among the sectors that have traditionally paid the highest CO2 tax. Therefore, the Norwegian petroleum sector has long had a substantially stronger incentive to carry out relatively expensive emission-reducing measures, as compared with most other players in Norway and abroad.

Over time, this has triggered emission-reducing efforts where the cost of measures has ranged up to this CO2 cost. In total, the petroleum industry estimates that the CO2 tax has triggered measures that have reduced CO2 emissions by 40 million tonnes since 1991. As many measures have already been triggered, the sector has few remaining emission-reducing measures with low costs. The work done under Climate Cure 2020 confirms this cost picture.

The best available technology must be used for the installation of new energy production equipment on facilities. The requirement for use of such technology has contributed to considerable reductions in emissions to air.

In 1996, the Storting resolved that an overview of energy needs and the costs associated with using power from shore instead of gas turbines must be submitted for all new field developments. Power from shore must be evaluated by the operator and followed up by the authorities in connection with processing each individual new plan for development and operation. Power from shore is discussed in more detail under Chapter 7.3.3.

Research aimed at reducing emissions to air was reinforced through the Climate Compromise. Publicly-funded petroleum research was to have a sharper focus on greenhouse gas emissions. Starting from 2009, NOK 25 million has been earmarked for research on energy efficiency and reduction of greenhouse gas emissions related to oil and gas production on the Norwegian Shelf. Relevant research challenges include reduced greenhouse gas emissions through less flaring (optimised running of processes, fewer shutdowns, etc.) and lower emissions from power generation (managing and exploiting gas turbines, etc.), as well as more efficient use of energy (optimising operations, heat recovery).

NOx emissions do not depend solely on fuel and efficiency, as is the case for the CO2 emissions, but also on combustion technology and turbine loads. The activity on the Norwegian Shelf has also been in the forefront of the work to develop gas turbines with lower NOx emissions – so-called low -NOx-turbines.

The Storting introduced an NOx tax3 in 2007, and excluded emission sources that entered into an environment agreement with the Norwegian state. In 2008, the Ministry of the Environment and the industry organisations signed the first NOx agreement, entailing a reduction of annual NOx emissions by 30 000 tonnes by the end of 2011, although this has subsequently been downgraded to 18 000 tonnes. A new agreement was signed in December 2010 with the aim of ensuring that Norway reduces its annual NOx emissions by an additional 16 000 tonnes by 2017. The Environment Agreement on NOx regulates the industry organisations’ obligations vis-á-vis the authorities to reduce total NOx emissions from the sources covered under the agreement. All operating companies with active operations on the Norwegian Shelf participate in this agreement. The rate of payments to the Industry’s NOx fund is NOK 11 per kilogram of NOx. These funds will be used to provide subsidies to enterprises that implement cost-effective NOx measures.

In 2009, a total of NOK 653 million was paid into the NOx fund. The oil and gas industry accounted for NOK 444 million (68 per cent) of that amount. Through 2009, 80 per cent of the emission reductions supported by the fund were triggered in the maritime sector, while 7 per cent of the fund’s emission reductions were carried out directly in the oil and gas sector, and 4 per cent on rigs. While NOx emissions in the petroleum sector have remained relatively stable over the last ten years, the oil and gas industry finances significant emission reductions in other sectors. The payment rate for the petroleum sector is nearly three times higher than for other sectors that participate in the NOx fund. Through the SDFI scheme and the tax system, the Norwegian state covers a substantial part of the revenues to the NOx fund.

Some light oil components (nmVOC) evaporate from the crude oil in connection with storage and loading. The oil terminal at Sture started to use technology to recover this oil vapour as early as in 1996. Following a requirement from the Climate and Pollution Agency to reduce emissions of nmVOC in connection with storage and loading offshore, an industrial cooperation agreement was signed in 2002 to satisfy these requirements in the most cost-efficient manner. During the last decade, this has led to the installation of oil vapour recovery technology for use on ships. Together with reductions in the volume of oil stored and loaded, this has yielded results. From 2001 to 2009, nmVOC emissions have been reduced from 250 000 to 45 000 tonnes.

Boks 7.3 Examples of emission-reducing measures

The emissions from the petroleum sector in Norway are subject to relatively strong policy instruments, and much has already been done to reduce the emissions to air from this sector. Emissions of CO2 from power production on the continental shelf account for about 90 per cent of the total emissions from the offshore activities. Many energy efficiency measures have been implemented after the introduction of the CO2 tax in 1991. In order to achieve a significant increase in energy efficiency over the longer term, a shift in technology and energy supply concept is necessary. This requires a long-term commitment to development, testing and implementation of new technology.

Combined cycle power is an example of emission-reducing technology where heat from turbine exhaust gas is used to produce steam, which is in turn used to produce electricity. Combined cycle power boosts energy efficiency, and is currently used on the Oseberg, Snorre and Eldfisk fields. These facilities are unique in a global offshore perspective. More low-NOx turbines have also been installed, which leads to a substantial reduction in NOx emissions.

Another example is the work related to injecting and storing CO2 in depleted oil or gas reservoirs, or in geological formations under water or on land. Since 1996, about one million tonnes of CO2 has been separated out on Sleipner in order to meet the gas quality requirements. This CO2 gas has been stored in the Utsira formation. When Gudrun starts producing and is tied in to Sleipner in 2014, the plan is to separate CO2 and store it in the Utsira formation. In April 2008, the Snøhvit field started to separate and store CO2, before the natural gas is cooled into liquid gas (LNG). The CO2 gas runs in a pipeline from the LNG facility on Melkøya and back to the field where it is injected and stored in the Tubåen formation, 2600 metres below the seabed. When there is full operation on Snøhvit, up to 700 000 tonnes of CO2 per year can be stored. These facilities where offshore CO2 injection takes place are unique in a global context.

The petroleum activities are subject to many policy instruments designed to reduce emissions to air, both in the planning and operations phases of the projects. Focus on reducing emissions to air has been, and will continue to be, important for the petroleum sector. Over time, the sector has had a higher CO2 cost than other sectors, both in Norway and abroad. This has already resulted in major emission reductions. Further measures in the petroleum sector will be relatively costly, a fact which was highlighted most recently in the Climate Cure Report.

7.3.2 Climate Cure 2020

Climate Cure 2020 has studied measures so that the Norwegian petroleum industry can reduce its overall greenhouse gas emissions by 5.5 million tonnes of CO2 equivalents. The measures have a price range from NOK 400–4000 per tonne of reduced CO2. There is great uncertainty associated with the estimated costs of measures and technology development.

These measures are major, complex industrial projects that will take time to realise. It has been deemed feasible for the petroleum sector to implement reductions of up to three million tonnes by 2020. In Climate Cure 2020, the petroleum sector encompasses all of the petroleum facilities on the Norwegian Shelf, as well as the land facilities at Kollsnes, Stura, Nyhamna, Melkøya, Mongstad and Kårstø. Climate Cure 2020 has studied measures within three areas:

Energy efficiency

Electrification

Carbon capture and storage (CCS)

Boks 7.4 Climate Cure 2020

In 2008, the Ministry of the Environment appointed an agency group under the leadership of the Climate and Pollution Agency. This group was called Climate Cure 2020. The mandate called for the final report to cover the following Chapters:

Assess the expected quota price in 2012, 2015 and 2020

Review international goals and instruments in climate policy. The development in Europe was to receive particular attention, including examining potential consequences for Norwegian policy instruments

Consider the need for new or adapted policy instruments in Norwegian climate policy. Particular emphasis was to be placed on policy instruments that contribute to fulfilling the goal of reducing emissions by 15 to 17 million tonnes by 2020. At the same time, there was a desire to identify policy instruments with long-term efficiency in terms of both management and costs.

The Norwegian Petroleum Directorate (NPD) has been responsible for administration of the petroleum sector analyses.

In 2009, the petroleum industry was responsible for 27 per cent of Norway’s total greenhouse gas emissions. Most of the emissions are linked to energy production. Introduction of the CO2 tax on the shelf in 1991 caused the companies to be more aware of energy-efficient operations. Many CO2-reducing measures have been triggered as a consequence of the tax. Reduced flaring and upgrading of turbines are examples of measures that have had substantial impact. There are still opportunities for reducing emissions through energy efficiency measures. Emission projections (reference path) for the petroleum sector include expected measures in energy efficiency and improved technology. The measures are not specified and amount to about one million tonnes of CO2 in 2020.

In Climate Cure 2020, the NPD has updated the estimated costs of measures from the report Power from shore to the Norwegian Shelf, submitted in January 2008. This report calculated the cost of measures and emissions reductions through replacing equipment for electrical power production on the facilities with power from shore. Updated costs of measures associated with area electrification (southern, central and northern parts of the North Sea and the Norwegian Sea) were estimated at between NOK 1350 and 3100 per tonne of reduced CO2. The NPD has studied measures that could provide overall emissions reductions of about 4.6 million tonnes. The updated analysis shows that the southern part of the North Sea is the area with the lowest measure costs for electrification, in part because the fields here have long expected lifetimes. In 1996, the Storting resolved that power from shore must be studied by the operator and followed up by the authorities in connection with each new development on the shelf. See also Chapter 7.3.3.

The NPD has also considered electrification of the land facility on Melkøya and parts of the Kårstø facility. CCS has also been considered for these facilities. These measures are mutually exclusive, which means that carbon capture and storage will not be relevant if the facility is electrified, and vice versa.

The costs of measures to reduce emissions for first-generation full-scale facilities are estimated at NOK 1300–2250 per tonne of CO2.

No costs of measures have been calculated for capture and storage of CO2 from offshore emission sources. Previous analyses indicate that the cost of measures will be considerably higher than for petroleum facilities on land. However, technological development could change the cost picture for offshore carbon capture and storage.

Use of CO2 to increase recovery from producing fields can provide a revenue contribution for carbon capture and storage in Norway. A high oil price can make it profitable to inject CO2 for increased recovery. However, this requires stable access to large volumes of CO2, larger than can be provided from Kårstø and Mongstad. No assessments have been made of the possibilities of using CO2 for improved recovery in Climate Cure 2020.

Together with e.g. the consultation submissions regarding this work, updated emissions estimates and macroeconomic analyses of measures, the studies carried out under Climate Cure will form the background material for the work on the upcoming Climate White Paper.

7.3.3 Power from shore

Starting from 1997, power from shore has been considered for all new developments and major modifications on the continental shelf. The Troll A platform was the first facility on the continental shelf to be run using power from shore. Subsequently, fields such as Ormen Lange, Snøhvit and Gjøa have been powered by electricity from land. Valhall and Goliat will receive power from shore when they come on stream. The Kårstø, Kollsnes, Tjeldbergodden and Nyhamna land facilities receive all or part of their power from the grid. Nearly 40 per cent of Norwegian gas production currently comes from these fields.

In 2009/2010, the NPD and NVE conducted an analysis of the power need for fields that already receive power from shore, or have decided to implement this. It is estimated that these fields will demand slightly less than 5 TWh in 2011, growing to nearly 6.5 TWh in 2020. It is important to view power from shore to the petroleum activities in context with the power system on land. Delivery of power to the petroleum activities beyond what has already been approved can be challenging. Building new transmission lines is important in order to make the onshore power system more robust.

The Ministry has also examined the possibilities of taking power from shore to existing fields on the continental shelf. The Norwegian Petroleum Directorate, the Norwegian Water Resources and Energy Directorate (NVE) and the Climate and Pollution Agency prepared the report entitled ”Power from shore to the Norwegian Shelf” in 2008. This analysis has been updated in connection with the work on the Climate Cure 2020 study.

The solution for energy supply to a petroleum facility is considered in connection with the authorities’ approval of a development. This takes place both in the impact assessment process and in the subsequent consideration of the development plan. All plans for development and operation of oil and gas fields must contain an analysis of the possibility of obtaining power from shore. This applies both to new field developments and to major modifications of existing facilities.

Access to power

In light of the desire for increased use of power from shore to facilities on the shelf, particular attention to the interface between the power system and the petroleum sector is important. A precondition for a solution involving power from shore is that it can be implemented without negative effects on the power system, and that the consideration for nature diversity must be safeguarded. Therefore, electrification of the shelf presumes simultaneous development of sufficient new power, or that there is sufficient new grid capacity to ensure that regional imbalances do not occur.

When estimating the cost of electrification measures, Climate Cure assumes that the necessary power is available at the presumed power price. In some cases, however, electrification could entail considerable extra costs associated with the development of new transmission lines.

Hydropower accounts for nearly all land-based production of electricity in Norway. The dominant role of hydropower means that Norwegian electricity production varies substantially from year to year, depending on water inflow to the reservoirs. It is important to take this aspect of the Norwegian power system into consideration, also when assessing power supply for the petroleum activities.

Production and consumption of electricity is not evenly distributed throughout the country, and the ability to transfer power between the various parts of the country depends on sufficient grid capacity. This entails that a planned increase in power consumption as a consequence of further electrification must be considered in relation to both regional and national reliability of supply. Establishment of new consumer units could occur faster than the establishment of new production and transmission grids. Therefore, careful planning is necessary to ensure that this type of establishment does not result in regional power system imbalances. Establishment of large new consumer units has contributed to the regional imbalances we have experienced in recent years.

Earlier, the establishment of enterprises involving high power consumption were often linked with the development of major production facilities. Much of the power production developed today consists of small-scale power plants and wind power with little regulation ability and significant geographical spread. This means that a solid electricity grid and transmission capacity is even more important than previously. A sound electricity grid is extremely important for delivering power from shore to new facilities on the continental shelf. Statnett’s development plan for 2010 aims for a significantly strengthened central grid, with an investment scope of about NOK 40 billion towards 2020. The plan also includes facilitation for planned petroleum activity and increased use of power from shore.

The Energy Act was amended on 1 January 20104 to improve coordination of investments in the grid, production and consumption, in part by introducing a requirement for the grid companies to tie-in new production facilities at all levels of the grid, when the production project and grid investment makes good socioeconomic sense. The previous practice of tying consumption to the regional and central grid was laid down in the law. If necessary, the grid companies must invest in grid facilities, but it is emphasised that tie-ins to the power system must wait until it is prudent from an operations viewpoint. In extraordinary cases, the Ministry can also grant exemptions from the tie-in and investment obligation for consumption. This entails that large consumer units must take greater responsibility for their own power supply, also within the petroleum sector.

The time aspect

Development projects on the Norwegian Shelf are comprehensive and require a substantial amount of time for both planning and development. To offset regional imbalances, operators of fields considering tie-in to the power system on land, or that plan to significantly increase existing power consumption, must contact the energy authorities and the relevant grid company at an early point in time.

Very extensive processes are associated with planning, licensing and developing the electricity grid. In many cases, development of the grid will take considerably longer than the development projects on the shelf. This underlines the importance of early contact by the developer to energy authorities and relevant grid companies.

Accordance between production, consumption and transmission capacity is important to prevent regional imbalances. This will be a significant issue for the Ministry when considering these issues.

The time dimension is also important when planning field developments as, in extraordinary cases, the operator can risk that the grid company is exempted from the tie-in and investment obligation for the field’s consumption. If such an exemption is granted, there is a risk that the projects will not be implemented, or that a different energy solution will have to be selected.

Statnett plays an important role as facilitator for consumption through its grid development work. The NPD plays a key role in mapping potential development in consumption in the various areas of the continental shelf. Such a mapping will include consumption from developers that have not progressed far enough for it to be natural for them to contact the energy authorities and relevant grid companies. This will ensure that knowledge concerning potential future power consumption in the petroleum sector is passed on for the benefit of central power sector players at the earliest possible point in time.

A specific assessment in each individual case is necessary in order to clarify the extent to which power from shore to fields on the continental shelf is a potential solution in terms of the power system.

Impact on emissions

Power from shore to the petroleum sector will reduce emissions of CO2 from the Norwegian Shelf. It will also contribute to a reduction of emissions within Norway’s borders as long as the power need is met by emission-free power production in Norway, or by imported power. Therefore, power from shore can be a way of reducing national emissions.

Increased power going to the petroleum sector will have an impact on the Norwegian power balance. Recent years have seen considerable variation as to whether Norway is a net importer or net exporter of power. The result of increased consumption as a consequence of power from shore to the petroleum sector will therefore reduce our exports or increase our imports of power.

Both the petroleum sector and production of electricity are subject to mandatory quotas under the EU ETS (Emission Trading System). The fundamental basis for this system is that the overall emissions are determined during the quota period. This means that reduced emissions from one location within the system are offset by increased emissions somewhere else. Therefore, in such a system, the only direct way to reduce emissions is to reduce the number of quotas. During the period from 2008–2010 (the Kyoto period), Norway will contribute around seven million tonnes of CO2 per year in reduced emissions through the EU ETS. We will accomplish this by awarding fewer quotas than were entailed by our estimated emissions from Norwegian enterprises subject to the quota obligation. The quota volume in the EU’s system is largely fixed. For the period 2013–2020, the quota volume in the EU system must be reduced by 21 per cent, or 1.74 per cent each year. The EU Commission has indicated that the quota volume could be further reduced by setting more rigorous European climate targets. Therefore, the quota system will be a key policy instrument for achieving reduced emissions in Norway and Europe over the next decade.

New developments

The authorities do a thorough job of assessing power from shore in connection with new developments and major modifications on the Norwegian Shelf. Historically, power from shore has not been a realistic alternative due to high costs and technical challenges. Over time, technological development has made power from shore more relevant. Power from shore still requires very significant investments, and will usually only be relevant in connection with major, independent developments or major modifications of larger fields.

A calculation of the costs of measures for power from shore is based on a number of assumptions regarding future development, including the scope of potential modification, investment and operating costs, field lifetime, as well as future electricity and gas prices. It is important that the calculations prepared in the years to come are based on realistic assumptions regarding field lifetime. When considering the cost of the measure for the Ekofisk Sør and Eldfisk II developments, for example, a cost of measures was estimated for lifetimes both to 2028 and 2049. Lifetime is an important factor in the cost level of the measures. Calculations prepared by the operator of the Ekofisk area provide a good illustration of this. The costs of measures were estimated at NOK 5310 per tonne of CO25 with a lifetime to 2028 and NOK 3585 for a lifetime to 2049.

Today, the Troll A platform, Gjøa, Ormen lange and Snøhvit all receive their power supply from shore. The new platform on Valhall, scheduled to start operation in 2011, will also receive power from shore. Of the new developments, it has been decided that Goliat will receive power from shore when the field starts operations in 2013. At the same time, the Kårstø, Kollsnes, Tjelbergodden and Nyhamna land facilities receive all or part of their power from the grid.

Tabell 7.1 Projects where power from shore has been considered since 2005.

Field | PDO year | Type of facility | Approx./ original reserves as of 31 Dec. 2010* million Sm³ o.e. | Energy supply |

|---|---|---|---|---|

Knarr | 2011 | FPSO | 8 | Traditional power supply |

Visund Sør | 2011 | Subsea to Gullfaks | 10 | Host facility |

Valemon | 2011 | Platform | 34 | Existing facility |

Eldfisk II | 2011 | Platform | 35 | Existing facility |

Ekofisk Sør | 2011 | Platform | 35 | Host facility |

Gudrun | 2010 | Platform | 20 | Host facility |

Marulk | 2010 | Subsea to Norne | 12 | Host facility |

Gaupe | 2010 | Subsea to Armada | 5 | Host facility |

Trym | 2010 | Subsea to Harald | 6 | Host facility |

Oselvar | 2009 | Subsea to Ula | 9 | Host facility |

Goliat | 2009 | Floater – Sevan | 39 | Power from shore |

Yttergryta | 2008 | Subsea to Åsgard | 2.5 | Host facility |

Morvin | 2008 | Subsea to Åsgard | 14 | Host facility |

Alve | 2007 | Subsea to Norne | 9 | Host facility |

Gjøa | 2007 | Floater – semi | 55 | Power from shore |

Vega and Vega Sør | 2007 | Subsea to Gjøa | 25 | Host facility |

Skarv | 2007 | FPSO | 70 | Traditional power supply |

Valhall Redevelopment | 2007 | Platform | 53 | Power from shore |

Yme | 2007 | Platform | 12 | Traditional power supply |

Rev | 2007 | Subsea to Armada | 7 | Host facility |

Volund | 2007 | Subsea to Alvheim | 7 | Host facility |

Tyrihans | 2006 | Subsea to Kristin | 77 | Host facility |

Oseberg Delta | 2005 | Subsea to Oseberg | 9 | Host facility |

Blane | 2005 | Subsea to Ula | 1 | Host facility |

Fram Øst | 2005 | Subsea to Troll C | 12 | Host facility |

Ringhorne Øst | 2005 | Wells from Ringhorne | 15 | Host facility |

Volve | 2005 | Platform | 9 | Traditional power supply |

Vilje | 2005 | Subsea to Alvheim | 8 | Host facility |

Enoch | 2005 | Subsea to Brae | 0.5 | Host facility |

* Reserves recorded for PDO received in 2011.

Kilde: Norwegian Petroleum Directorate.

A review of all developments approved since 2005 shows that four of the developments have a solution entailing power from shore, cf. Table 7.1. As regards subsea developments (including new wells), power from shore is only realistic if the host platform already has this as its power solution, such as is the case for Vega and Vega Sør. If a host platform receives power from shore in the future, the tied-in resources will also be produced with power from shore. The Gudrun platform gets its power from Sleipner, and will therefore also receive power from shore if Sleipner were to adopt such a solution in the future.

A coordinated development could be very beneficial in the event of multiple smaller discoveries in the same area. A coordinated development can also make power from shore a more realistic alternative than if the fields are developed individually. The NPD plays an important role in ensuring that these alternatives are studied. The assessments made by the companies and the authorities in each individual case will determine whether or not power from shore is an expedient solution.

Existing fields

The energy needs of most of the fields on the shelf are currently met by gas turbines. Extensive modifications and retrofits are usually necessary in order to modify these units to receive power from shore. This is cost-intensive and requires available space on the facility. A lengthy shutdown would, for example, entail significant losses in the form of deferred sales revenues. Such solutions are more realistic when the existing energy supply must be replaced or upgraded.

Power from shore to existing fields on the Norwegian Shelf has been analysed and considered on a number of occasions. In 2002, the NPD and the Norwegian Water Resources and Energy Directorate prepared a report on power from shore to the Norwegian Shelf. This report was updated in 2008 as a consequence of guidelines in the 2007 Climate White Paper. The Petroleum Safety Authority Norway and the Climate and Pollution Agency also participated in the update. The recently presented Climate Cure report also estimates the costs of measures for power from shore, both for existing and new fields.

The Climate Cure report shows costs of measures varying from NOK 1350 per tonne of CO2 and upward for power from shore to existing areas (power from shore to multiple facilities at the same time). For individual fields, however, it will in most cases be far more costly to replace the power supply on individual facilities with power from shore.

All of the power from shore projects presented in Climate Cure are based on partial electrification. This means that only the power from the turbines that generate electricity will be replaced with power from shore. About half of the turbines on the Norwegian Shelf produce electric power, while the rest of the turbines directly run equipment such as pumps and compressors. In total, the turbines account for 75 per cent of the CO2 emissions from the petroleum sector. The potential for emission reductions as a consequence of partial electrification will therefore be limited to about half of this.

In some cases in connection with major modifications of existing fields, power from shore can be a real alternative, as a rule in cases where there is talk of replacing old facilities on fields with new facilities. These types of cases normally require a new development plan, which means that power from shore is considered on an equal basis with new developments. Valhall is an example of the possibility of running power from shore to existing fields that are rebuilt. The development plan for redevelopment of the field was approved in 2007. The new field centre on Valhall will receive power from shore and replace two older facilities, with planned start-up in 2011.

The Government will:

Require consideration of power from shore as an energy solution for new fields and in connection with major modifications of existing fields, including consideration of relevant lifetime.

Follow up to ensure that operators of new field developments in the petroleum sector apply for tie-in to the grid at an early point in time, in those cases where power from shore is relevant.

Statnett will facilitate future power consumption, including major specific increases in petroleum sector power consumption, if this is socioeconomically profitable.

7.4 Acute discharges to sea

It is important to differentiate between normal and acute discharges to sea. Acute discharges to sea are spills that are not planned, and not approved by the Climate and Pollution Agency. Acute discharges to sea can consist of oil, chemicals and drilling fluids.

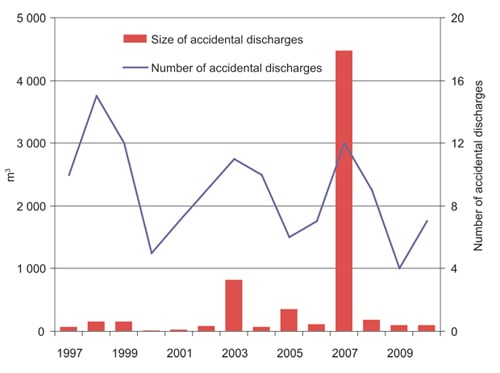

The great majority of acute discharges are small, but some larger oil spills can also occur. There were 139 acute discharges of oil in 2010, of which 132 were less than one cubic metre. The total volume of all the discharges was 105 m3, cf. Figure 7.6.

We can never reduce the risk of acute pollution to zero, which means that good risk management is even more important. In order to achieve this, we must work to reduce both the likelihood and the consequences of acute discharges. Under the Pollution Control Act, the operating companies are both responsible for and have a duty to establish necessary emergency preparedness to deal with acute pollution.

The environmental consequences of an acute discharge of oil depend on many factors. While the size of the spill is obviously the key factor, the location, season, wind speed, current and emergency preparedness will be crucial as regards the scope of the damage. Most spills in Norway have occurred from ships near the coast.

Figur 7.6 Acute discharges of oil greater than 1 m3 from the petroleum sector.

Kilde: Norwegian Petroleum Directorate.

There has been extensive growth in the activity level in the petroleum industry, without an accompanying increase in discharges. Over time, the petroleum activities on the Norwegian Shelf have experienced a varying number of smaller acute discharges and some larger acute spills. During the course of 40 years of activity, there have been only three incidents involving discharges of oil greater than 1000 cubic metres: the Bravo blowout in 1977, the spill from Statfjord C in 1989 and from Statfjord A in 2007. To date, there have been no acute discharges of oil from the petroleum activities on the Norwegian Shelf that have reached land.

Boks 7.5 Deepwater Horizon accident

On 20 April 2010, there was an explosion on the Deepwater Horizon drilling rig as it was in the process of completing drilling on the Macondo prospect in the Gulf of Mexico. The rig burned for two days before it sank. The well was shut in mechanically on 16 July, and declared permanently plugged on 19 September. The accident claimed 11 lives, and caused the largest blowout ever experienced in US waters. About 800 000 m3 of oil leaked out of the well until the discharge could be stopped. US authorities have estimated that more than 40 per cent of the oil was either naturally broken down or evaporated. Seventeen per cent of the leakage from the well was recovered at the wellhead. Another 16 per cent was collected, dissolved using chemical dispersants or burned.

The investigation report drawn up by the Presidential commission was submitted in January 2011. The main conclusion was that the accident could have been prevented, and that the underlying causes were: ”a complex and interwoven series of mechanical failures, bad decisions, design, operational implementation and team cooperation”.

The Norwegian Ministry of Labour will cover the HSE authorities’ follow-up of the Deepwater Horizon accident in the Gulf of Mexico in an upcoming Storting white paper.

The accident took place in one of the USA’s most important fishing areas. One-third of all the seafood in the US comes from this area. Fishery activity was halted throughout large parts of the areas immediately after the accident. In June 2010, 37 per cent of the waters in the US sector of the Gulf of Mexico were closed for fishing. On 19 April 2011, the last remaining closed areas above the discharge point were reopened for fishery activity. Differences in seafood quality before and after the accident have been noted to a limited extent. Even the extreme levels that were measured are well within the US authorities’ requirements for seafood. The region is also one of the US’ most important tourism areas, with tourism accounting for an annual turnover of more than NOK 240 billion (USD 40 billion).

A total of 8 183 seabirds, 1 144 sea turtles and 109 sea mammals were found, dead or alive, that were most likely affected by the spill. Four of 100 dead sea mammals were observed fouled with oil. A total of 210 km of the coastline was moderately to heavily affected by oil. The immediate consequences of the accident have not been as extensive as many feared in the early phases of the incident. It is too early to say anything about the overall consequences of the spill on the ecosystem. Almost one-quarter of the spill remained in the marine environment. In addition, there has been no previous experience with such extensive use of dispersants.

It will take years before we have a complete overview of the effects of the accident. A lot of work will be done to map this in the years to come. BP alone has allocated NOK 3 billion (USD 500 million) towards independent studies of the consequences of the spill. A number of investigations and reports related to follow-up of the accident in the USA are still under preparation.

7.4.1 Risk of acute discharges of oil

The Petroleum Safety Authority Norway monitors risk development in the petroleum activities in several different ways. One important tool in this context is the mapping work in RNNP – Risk level in the petroleum activity. Since 2001, extensive data material has been gathered under the auspices of RNNP and analysed primarily with a view towards risk related to major accidents and working environment.

In 2010, the Petroleum Safety Authority published the report entitled “RNNP – acute discharges 2001–2009”. This report provides an analysis of the above-mentioned basic data, supplemented with information from the Environmental Web database, with a view towards acute discharges (actual and potential) in the period 2001–2009. A total of 452 acute discharges of crude oil have been reported on the Norwegian Shelf from 2001 to 2009. 439 of these end up in the lowest category, 0 to 10 tonnes.

The RNNP data show that the number of acute discharges of crude oil to sea on the Norwegian Shelf, viewed together, was more than halved in the period 2001–2004, while the level remained constant in the period 2004–2009. There has been a clear reduction in the number of crude oil spills per year in the North Sea. This reduction was greatest in the period up to 2003, while there was a more modest reduction in the last six years. In the Norwegian Sea there was an increase in the early 2000s, followed by a substantial reduction, and then a stable level from 2004.

Looking at the last five-year period, there have been 15 incidents in the petroleum activities that have resulted in discharges larger than 5 m3, cf. Table 7.2. By far most of the spills are small, and only eight spills were larger than 10 m3 during the period. These spills have many different causes. The majority of the spills relate to operational errors, and a large percentage are related to diesel leaks/discharges. Information like this is important in the preventive work to reduce the risk of acute discharges to sea.

Tabell 7.2 Acute discharges greater than 5 cubic metres in the period 2005–2009.

Field | Year | Cubic metres of oil | Description |

|---|---|---|---|

Statfjord | 2007 | 4400 | Loading hose rupture in connection with loading crude oil at Statfjord A |

Norne | 2005 | 340 | Valve in wrong position when flushing flowlines and risers |

Tordis | 2008 | 100 | Leak to seabed from injection well for produced water. |

Draugen | 2006 | 98 | Discharge in connection with loading crude oil |

Statfjord | 2009 | 95 | Oil-contaminated water to sea. |

Statfjord | 2008 | 50 | Oil leak in Statfjord A leg, controlled discharge to sea for safety reasons |

Åsgard | 2007 | 22 | Incorrect valve setting led to overflow from diesel tank |

Ekofisk | 2008 | 12 | Incorrect operation in connection with draining raw diesel tank. |

Snorre | 2007 | 10 | Operational error led to diesel going to sea from fire pump. |

Snorre | 2007 | 10 | Valve and operational error led to diesel going to sea via fire pump. |

Gullfaks | 2005 | 8.8 | Incorrect operation following repair of flotation cell |

Statfjord | 2007 | 8.5 | Leakage of seal oil to open drain. |

Heidrun | 2008 | 7 | Discharge of diesel oil to sea after diversion to new diesel tank |

Statfjord | 2005 | 7 | Pipe leakage |

Draugen | 2008 | 6 | Coupling rupture due to pressure build-up when loading crude oil |

7.4.2 Policy instruments and measures to reduce the risk of acute discharges

The risk of acute discharges is equal to the likelihood of an acute spill multiplied by the associated consequences. To reduce this risk, we must therefore focus on measures that can reduce the likelihood and consequences of acute discharges.

The RNNP work is an important supplement to the factual basis for prioritising accident prevention work so that the likelihood, and thus also the risk, of acute discharges can be reduced. In addition to illustrating the development of risk on the Norwegian Shelf as a whole, it is also organised so as to view each sea area independently, making this also suitable for use in the work on management plans.

The report entitled “Technology and knowledge status of significance for reducing the risk of undesirable incidents that can lead to acute discharges to sea in connection with petroleum activities in the Northern Areas” was released in January 2010. The report prepared by the Petroleum Safety Authority Norway, the University of Stavanger and the International Research Institute of Stavanger confirms that technology and knowledge development is crucial for keeping accident risk at a low level. This can reduce the likelihood and consequences of acute discharges. It is therefore important that the industry and the authorities learn from undesirable incidents, so as to reduce the risk of new acute discharges.

Oil spill preparedness on the Norwegian Shelf is important in reducing the consequences of potential major acute discharges. The Climate and Pollution Agency sets requirements for oil spill preparedness, and the operating companies are responsible for combating oil spills from petroleum facilities on the seabed or the sea surface. This responsibility includes strategic management. The Norwegian Clean Seas Association for Operating Companies (NOFO), on behalf of the operators, is responsible for strategic and operational management of the oil spill response resources that are used. NOFO establishes and safeguards oil spill preparedness on the Norwegian Shelf in order to combat oil pollution on behalf of 25 operating companies, both in open waters, in coastal areas and in the beach zone. Both public and private sector oil spill resources are combined in the Norwegian preparedness model. The cooperation between municipal and state oil spill preparedness and NOFO means that Norway’s overall emergency preparedness resources are available 24/7. The Norwegian Coastal Administration handles the State’s responsibility for acute preparedness and will supervise oil spill campaigns. The Norwegian Coastal Administration can also consider whether the State should take over as leader of an oil spill campaign.

There is no guarantee that a future oil spill will not reach vulnerable resources in the sea or on land. Oil fields are being developed further north than ever before. The risk of an acute spill reaching land increases (seen in isolation) when the activities are carried out closer to the coastline. This requires development of new equipment, so as to discover, monitor and recover pollution. The geographical spread of the activities all along the coastline could also initiate a need for more equipment.

NOFO has access to considerable oil spill response resources that can be mobilised to all parts of the Norwegian Shelf. This includes 20 dedicated full-time employees, 50 on-call/reinforcement personnel from operating companies, 25 oil recovery vessels, 25 towboats, 20 ocean-going mechanical recovery systems and 80 people associated with 5 oil spill response bases. There are large stores of dispersants, oil spill recovery equipment for operations near the coast with access to fishing vessels, and special teams for organising and managing the need for operations in the beach zone. The oil spill response work focuses on 5 barrier levels, where Barrier 0 is preventing the oil from reaching the water, Barriers 1, 2 and 3 are related to recovery at sea and Barrier 4 is clean-up in the beach zone.

There are also restrictions on exploration drilling in oil-bearing layers during certain parts of the year. This is done to limit environmental consequences for e.g. fish and birds as a consequence of potential acute oil discharges in connection with exploration drilling. These restrictions are specified in the license documents from the authorities or in the management plan for a specific sea area. Requirements relating to preparedness against acute pollution are stipulated for all exploration drilling.

7.5 Safety on the Norwegian Shelf

The Ministry of Labour/Petroleum Safety Authority Norway are responsible for the regulations relating to, and supervision of, both technical and operational safety, as well as the working environment in the offshore petroleum activities and certain land facilities. The authorities’ responsibility covers all phases of the activity, such as planning, engineering, construction, use and subsequent final removal, if applicable.

RNNP was initiated in 1999/2000 to develop and apply a measurement tool to illustrate development in the risk level on the Norwegian Shelf. This work occupies an important position in the industry in that it contributes to a unified understanding of risk development among the parties. The RNNP work follows risk level developments using various methods such as incident indicators, barrier data, interviews with key sources, working seminars, field work and a major questionnaire survey every other year. The results are presented in annual reports, which also provide a basis for implementing measures to counteract negative trends.

Overall, the latest RNNP survey shows a weak negative trend in the risk picture in 2010. The overall indicator for major accidents has levelled out in the last five-six years, both for production facilities and mobile facilities. Continuous improvement is the goal.

There were no fatal accidents on the shelf in 2010, and the frequency of serious personal injuries has shown positive development in recent years. The injury rate for the entire shelf is now 0.68 serious personal injuries per million hours worked. This is significantly lower than in the previous ten-year period.

Up to 2008, we saw a consistently positive development in the number of well control incidents. However, there was a sharp increase in the 2008–2010 period, from 11 incidents in 2008 to 28 in 2010. The increase is also clear when taking into account the development in activity level (number of wells drilled). The Petroleum Safety Authority Norway has asked the industry to address the challenges associated with hydrocarbon leaks and well control incidents, urging it to come up with concrete measures that can contribute to a trend in the right direction.